Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

Tantalum Wire Mesh

Material: pure tantalum (Ta≥99.95%) or tantalum alloy

Wire Diameter: 0.016mm – 10.0mm

Mesh: 2 mesh – 200 mesh

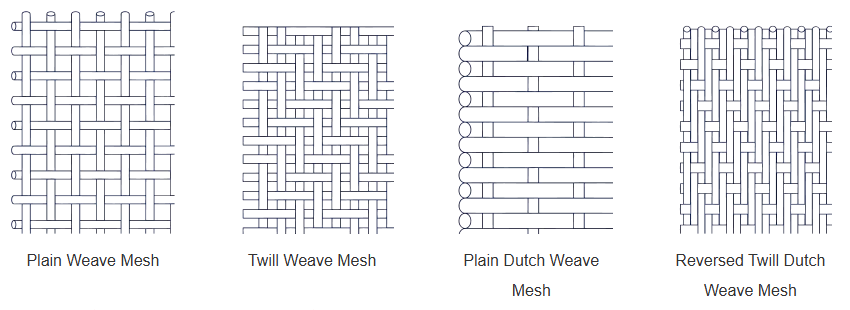

Weaving Method: plain weave, twill weave, dense weave

Width: 0.5m – 2m (customizable)

Length: 10m – 50m (customizable)

Thickness: 0.1mm – 2mm

Porosity: 10% – 90% (adjusted according to demand)

Standard: AISI, ASTM, JIS, DIN, EN, BS

Surface Treatment: polishing, oxidation treatment

Delivery: 10 days, according to specification and stock

Tantalum Wire Mesh is a metal mesh woven or welded from high-purity tantalum wires. It has strong corrosion resistance, high temperature stability, excellent conductivity and biocompatibility.

The manufacturing process of tantalum wire mesh is relatively complex and requires high-precision control to ensure its performance and quality. Hebei Cechen New Material Co., Ltd., as a professional tantalum wire mesh manufacturer, provides high-quality tantalum mesh, tantalum wire mesh, tantalum woven mesh, tantalum welded mesh and other products, supporting customization of multiple specifications to ensure that different industrial needs are met.

| Catalog No. | Size | Material | Standard | Surface |

| TA1052 | 1-150 mesh | Tantalum UNS R05200 UNS R05400 | ASTM B365 | As rolled |

| Material | Mesh | Processing |

| Tantalum Wire Dia.: 0.05mm-10.0mm | 1-150 mesh Aperture rate: 10%-90% Size: 10mm-2000mm Width x Length | Plain Weave and Twill Weave |

A variety of weaving processes are available to meet the needs of different industries.

| Element | R05200 (%,Max) | R05400 (%,Max) |

| C | 0.01 | 0.01 |

| O | 0.015 | 0.03 |

| N | 0.01 | 0.01 |

| H | 0.0015 | 0.0015 |

| Fe | 0.01 | 0.01 |

| Mo | 0.02 | 0.02 |

| Nb | 0.1 | 0.1 |

| Ni | 0.01 | 0.01 |

| Si | 0.005 | 0.005 |

| Ti | 0.01 | 0.01 |

| W | 0.05 | 0.05 |

The production process of tantalum wire mesh includes multiple steps such as tantalum wire stretching and processing, weaving process, and post-processing process.

1. Production and processing of tantalum wire

● Preparation of raw materials: The raw materials of tantalum metal are usually tantalum powder or tantalum ingots. These raw materials need to be smelted and cast to form large tantalum billets.

● Wire drawing: The tantalum billet is heated to an appropriate temperature and stretched through a wire drawing machine to gradually draw out tantalum wires of different diameters. The temperature and speed need to be precisely controlled during the wire drawing process to ensure the uniformity and surface smoothness of the tantalum wire.

● Annealing: In order to eliminate the internal stress in the tantalum wire, the tantalum wire is usually annealed. Annealing can make the mechanical properties of the tantalum wire more uniform and improve its ductility and strength.

2. Weaving process

● The weaving process of tantalum wire is the core step in the production of tantalum wire mesh. Common weaving methods include plain weave, twill weave, Dutch weave, etc.

3. Welding and fixing

● In some tantalum wire mesh applications, the edge of the tantalum mesh needs to be welded or fixed with tantalum wire to ensure the structural stability and ease of use of the mesh.

4. Post-processing process

● The post-processing process of tantalum wire mesh includes cleaning, surface polishing, oxide removal and other steps. Post-processing helps to improve the surface finish of tantalum wire mesh, further improving its corrosion resistance and service life.

5. Inspection and quality control

● After the tantalum wire mesh is produced, we will conduct strict inspection to ensure that it meets the specifications. Common inspection items include: mesh size inspection, tensile strength test, corrosion resistance test, mesh defect detection, etc.

● Filtration: Tantalum Wire Mesh is used in filtration applications due to its chemical resistance and ability to withstand high temperatures. It is commonly used in filters for gas masks, respirators, and other personal protective equipment.

● Electrodes: Tantalum Wire Mesh is used in electrodes due to its electrical conductivity and high chemical resistance. It is commonly used in fuel cells, electrolytic capacitors, and other electrochemical devices.

● Structural Reinforcement: Tantalum Wire Mesh is used as a structural reinforcement material due to its high tensile strength and ductility. It can be used in aircraft, automotive, and other structural applications that require lightweight yet strong materials.

● Heat Exchangers: Tantalum Wire Mesh is used in heat exchangers due to its high-temperature tolerance and good thermal conductivity. It can be used in various industrial processes that require heat transfer and temperature control.

● Medical Implants: Tantalum Wire Mesh is biocompatible and can be used in medical implants such as hip replacements and orthopaedic devices that require high strength and corrosion resistance.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.

Products Categories

Contact Us

Hello, welcome to submit any questions and suggestions. We will reply to you as soon as possible. Thank you for your support and help.

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.