Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Whatsapp: +86 177 3218 7602

E-mail: info@ccwirecloth.com

Molybdenum Wire Mesh

Material: pure molybdenum wire or molybdenum alloy wire

Wire Diameter: 0.1 mm to 5 mm

Aperture: 0.1 mm to 10 mm

Mesh: 1 to 400 and Customized

Purity: 99.95% to 99.98%

Melt Point: 2622°C

Density: 10.22 g/cm³

Thermal conductivity: 1.397 watts/cm/°C

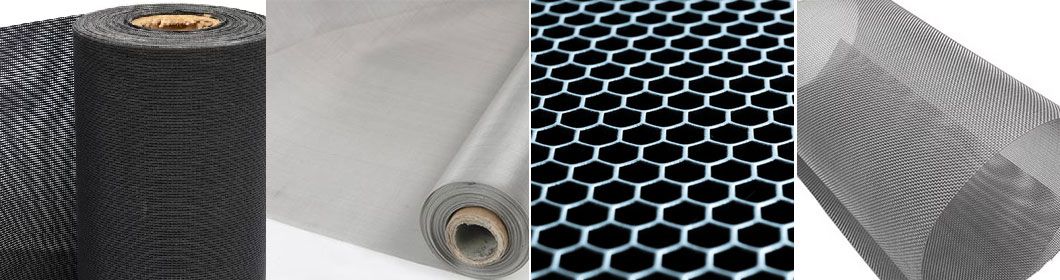

Both square, rectangular mesh patterns, roll mesh are available.

Molybdenum wire mesh is a type of woven or welded wire mesh made from molybdenum, a refractory metal known for its high melting point, strength, and resistance to corrosion and wear. Its unique characteristics make it used for filtering and screening in high temperature fields such as furnaces, petroleum, chemicals, food, medicine, machinery, etc. If you need a mesh that can withstand extreme conditions, molybdenum mesh is an excellent choice.

Molybdenum Wire Mesh is a type of woven wire mesh, which is made of pure molybdenum wires or alloy wires. According to the weaving patterns, molybdenum wire mesh has plain weave, twill weave, dutch weave patterns with square and rectangular shaped holes on surface.

| Mesh/Inch | Wire Diameter (mm) | Opening (mm) | Opening Area % | Weight kg/m2 | Mesh/Inch | Wire Diameter (mm) | Opening (mm) | Opening Area % | Weight kg/m2 |

| 1 | 4.87 | 20.523 | 68% | 15.40 | 40 | 0.25 | 0.385 | 37% | 1.62 |

| 2 | 3.04 | 9.652 | 58% | 12.00 | 40 | 0.23 | 0.401 | 40% | 1.37 |

| 2 | 2.60 | 10.033 | 62% | 8.78 | 40 | 0.22 | 0.415 | 43% | 1.25 |

| 3 | 2.00 | 6.467 | 58% | 7.80 | 40 | 0.19 | 0.445 | 49% | 0.93 |

| 3 | 1.60 | 6.867 | 66% | 4.99 | 50 | 0.19 | 0.318 | 39% | 1.17 |

| 4 | 1.60 | 4.750 | 56% | 6.65 | 50 | 0.15 | 0.335 | 49% | 0.73 |

| 4 | 1.20 | 5.150 | 66% | 3.74 | 50 | 0.20 | 0.478 | 89% | 1.29 |

| 5 | 1.20 | 3.880 | 58% | 4.67 | 60 | 0.15 | 0.273 | 42% | 0.87 |

| 5 | 1.00 | 4.080 | 65% | 3.24 | 60 | 0.16 | 0.263 | 39% | 0.99 |

| 6 | 1.20 | 3.033 | 51% | 5.61 | 70 | 0.12 | 0.243 | 45% | 0.65 |

| 6 | 0.90 | 3.333 | 62% | 3.15 | 80 | 0.12 | 0.198 | 39% | 0.74 |

| 8 | 0.61 | 2.565 | 65% | 1.93 | 90 | 0.12 | 0.162 | 33% | 0.84 |

| 10 | 0.50 | 2.032 | 64% | 1.62 | 100 | 0.10 | 0.154 | 37% | 0.64 |

| 10 | 0.45 | 2.083 | 67% | 1.31 | 100 | 0.076 | 0.177 | 49% | 0.37 |

| 12 | 0.50 | 1.609 | 58% | 1.94 | 120 | 0.09 | 0.122 | 33% | 0.63 |

| 14 | 0.42 | 1.397 | 59% | 1.60 | 120 | 0.08 | 0.132 | 39% | 0.49 |

| 16 | 0.38 | 1.212 | 58% | 1.50 | 140 | 0.06 | 0.121 | 45% | 0.32 |

| 18 | 0.28 | 1.317 | 65% | 0.91 | 150 | 0.065 | 0.104 | 38% | 0.41 |

| 20 | 0.40 | 0.870 | 47% | 2.07 | 180 | 0.06 | 0.081 | 33% | 0.42 |

| 20 | 0.32 | 0.955 | 57% | 1.33 | 180 | 0.05 | 0.091 | 42% | 0.29 |

| 24 | 0.28 | 0.784 | 55% | 1.22 | 200 | 0.05 | 0.077 | 37% | 0.32 |

| 24 | 0.23 | 0.824 | 61% | 0.82 | 250 | 0.04 | 0.062 | 37% | 0.25 |

| 26 | 0.25 | 0.723 | 55% | 1.32 | 270 | 0.028 | 0.066 | 49% | 0.13 |

| 28 | 0.27 | 0.633 | 49% | 1.32 | 280 | 0.03 | 0.061 | 45% | 0.16 |

| 28 | 0.23 | 0.673 | 55% | 0.96 | 300 | 0.04 | 0.045 | 28% | 0.31 |

| 30 | 0.23 | 0.613 | 52% | 1.03 | 325 | 0.035 | 0.043 | 30% | 0.25 |

| 32 | 0.30 | 0.494 | 39% | 1.87 | 400 | 0.038 | 0.038 | 37% | 0.16 |

| Molybdenum Chemical Composition (%) | ||||||

| C | Fe | Ni | O | Si | N | Mo |

| 0.01 | 0.01 | 0.005 | 0.007 | 0.01 | 0.02 | Rem |

Both Square, Rectangular Mesh Patterns, Roll Mesh are Available.

● Square mesh patterns: Molybdenum wire mesh square grid means that the horizontal and vertical spacing of the grid is equal, forming a uniform square mesh. This grid shape is suitable for applications that require uniform filtration and precise screening.

● Rectangular mesh patterns: Rectangular grid refers to the grid with unequal horizontal and vertical spacing, forming a rectangular mesh. This grid shape is usually used for specific screening or filtering needs, especially when it is necessary to process materials of different particle sizes.

● Strong high temperature resistance: Molybdenum metal itself has an extremely high melting point (about 2623°C), so it is often used for filtering, screening and supporting in high temperature environments.

● Excellent corrosion resistance: Molybdenum wire mesh has strong resistance to most acids, alkalis and oxidizing environments

● High strength and high rigidity: Molybdenum wire mesh can maintain stable performance even in situations with high pressure and high strength requirements

● Good antioxidant properties: Molybdenum wire mesh will not oxidize rapidly in high temperature oxygen environment

● Fine filtration performance: Molybdenum wire mesh has a relatively uniform mesh structure and is suitable for applications with high requirements for fine filtration.

● Good electrical conductivity: Molybdenum wire can provide the necessary conductivity in the fields of electronic components, conductive devices, etc.

● Resistant to high pressure and high flow rate: Molybdenum wire mesh can withstand greater pressure and flow rate, and is suitable for filtering and separating high-flow gas or liquid applications.

● Radiation resistance: Molybdenum mesh can be used for radiation shielding in medical equipment due to its high density.

Hebei Cechen New Material Co., Ltd. is a comprehensive enterprise integrating production and sales. We have 39 years of production and sales experience. Our products are sold to more than 30 countries and regions around the world, including the United States, Europe, the Middle East, and Southeast Asia. We specialize in the production of high temperature resistant, corrosion resistant, and fine filtering molybdenum wire mesh. If you need high-quality and high-precision molybdenum wire mesh, please contact us.

● High-quality raw materials: We use high-quality molybdenum wire as raw material, which can make the molybdenum wire mesh more durable and wear-resistant, greatly reducing its replacement frequency.

● Customizability: Our molybdenum wire mesh can be customized according to your specific needs, including mesh size, weaving method, thickness, etc., to meet the special requirements of size and performance in different fields.

● Strict quality inspection process: We have professional quality inspectors who conduct strict quality inspections before products enter the factory, production process changes, and products leave the factory to ensure that you get reliable products.

● Competitive prices: We have our own factory and all the production process of molybdenum wire mesh is completed by ourselves, so we can offer more competitive prices.

● Short construction period: We have a large amount of inventory. If you are in urgent need of the product, please contact us and we will be able to provide you with the product you need as soon as possible based on the inventory.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.

Products Categories

Contact Us

Hello, welcome to submit any questions and suggestions. We will reply to you as soon as possible. Thank you for your support and help.

Need A Custom Solution?

Our team is filled with seasoned experts who can't wait to help you find the right solution for your business.

Get In Touch

Whether you have a question about our products or services, or simply want to learn more about what we do,we are always here to help.